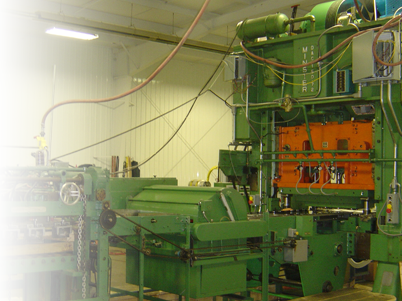

Cupping Press Systems

RAM Cupping Systems

assure the utmost quality.

RAM high-quality cupping systems assure you the utmost quality can production and high efficiencies during the entire can-making process.

Custom cupping system features include:

- Cam-driven feed roll assembly for progressive and synchronized feeding of coil stock

- Eccentric shaft, vertical double action, high-speed press built for high efficiency and high volume. Maximum reliability and dependability.

- Centrally controlled lubrication system to monitor press operation and die guide pin components

- Multi-station die set and tooling assembly to form conventional or reformed beer and beverage cups out of aluminum or steel for drawn and iron process

- Special blank and draw-through die assembly with integrated dual lane cup discharge conveyor system and recessed scrap chopper for high-speed, high-volume production

- Triple pneumatic cushion assembly for each cupping die station

- Consistent product from one cup to the next without thickening or thinning of metal

- Tooling designed for maximum life incorporating carbide wear parts. Minimal maintenance requirements reduce production downtime, product spoilage and increase productivity.

- Adaptable for processing coiled aluminum or steel materials

- Reduced scrap generation achieved through maximum use of metal widths, with controlled web and edge tolerances.

- Special die loading assembly.

- Computerized designed programmable logic control electronic and electrical line system. Incorporates press and die protection devices plus safety features.

- Cup geometry designed to use the lightest possible metal gauge for container size.

Contact RAM Innovative Technologies for more information about our cupping press systems. Call (330) 904-8039 or email ramgroup@raminnovative.com.